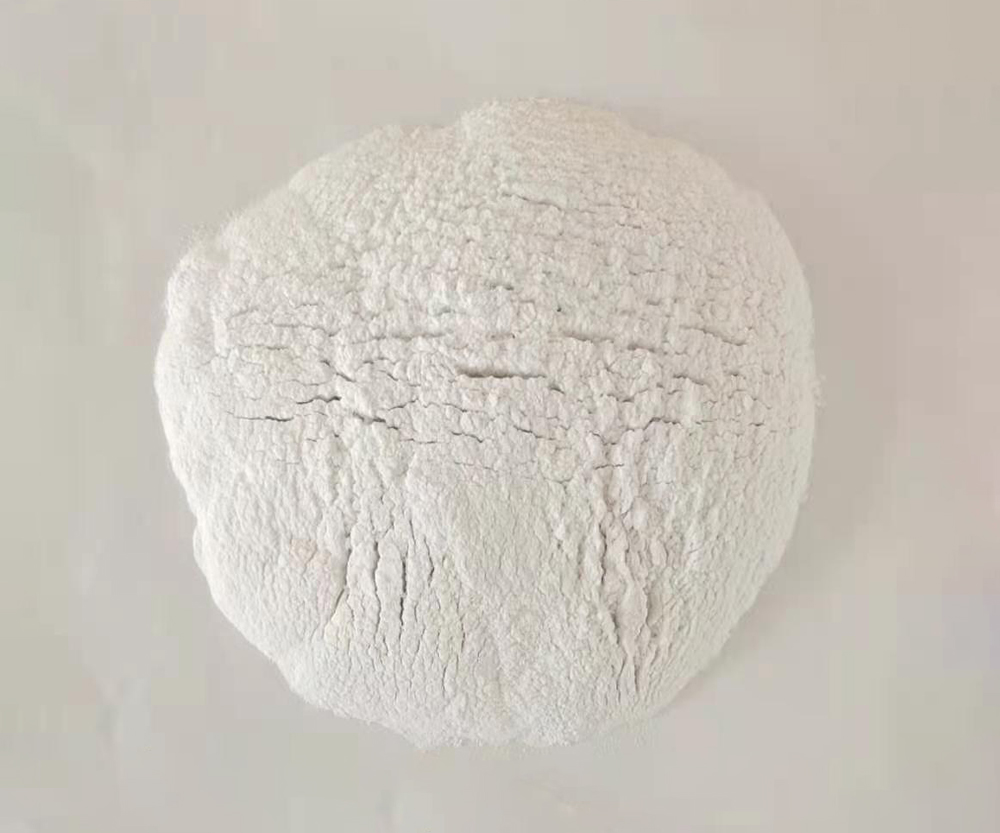

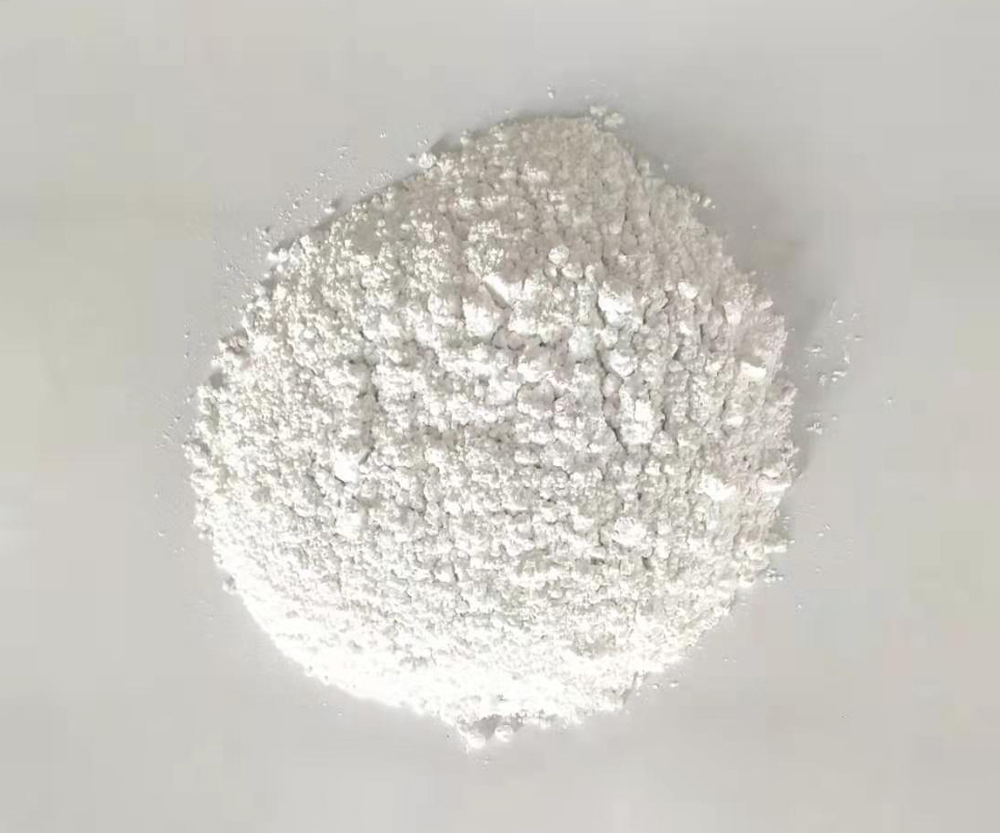

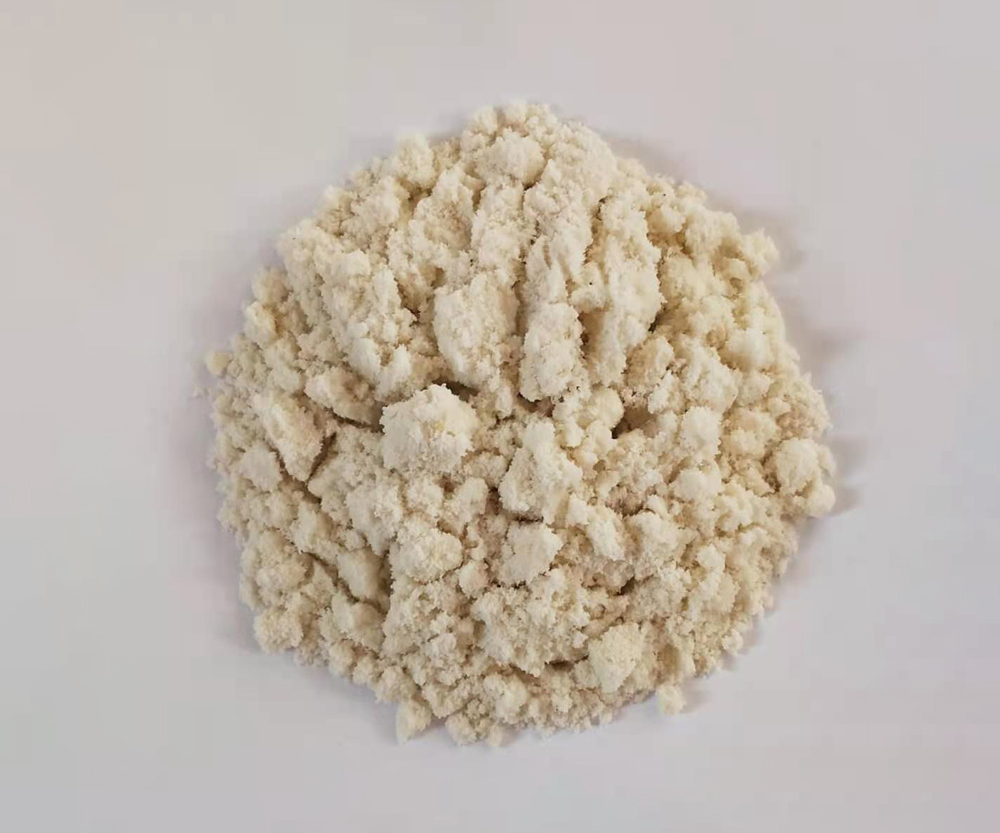

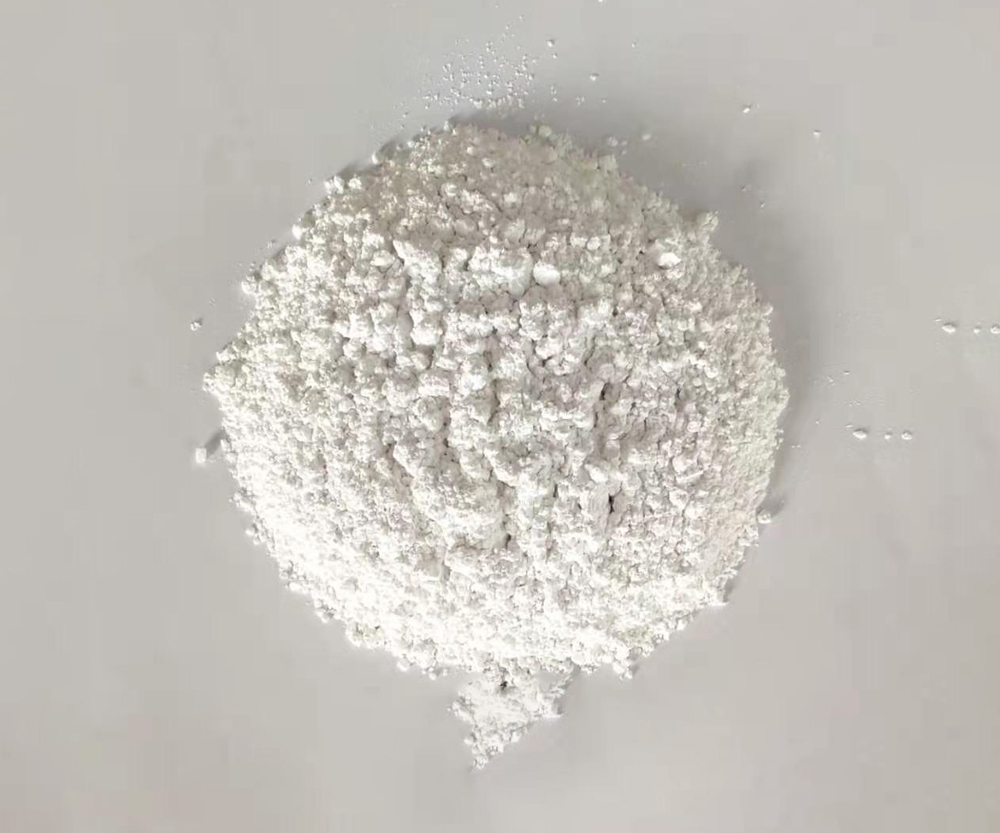

With the further reduction of the profit margin of iron and steel companies, some progressive process control methods have even been adopted in exchange for enough cost space, which has become the mainstream measures for some iron and steel companies to reduce costs and improve efficiency. In order to reduce the cost of sinter, 180-200 mesh dolomite powder was used instead of high magnesium dust. The main role of MgO content in sinter is reflected in the slag discharge system of blast furnace smelting process, which provides a good foundation for improving the utilization rate of blast furnace and optimizing other economic indicators.

Therefore, as long as the dolomite powder is well controlled to stabilize the MgO content in the sinter, it will not have a significant impact on the blast furnace slag system. After preliminary research and analysis, the main theoretical blind area of adding dolomite powder in sintering proportioning process is to control fuel consumption and sinter particle size and drum.

中文(簡(jiǎn)體)

中文(簡(jiǎn)體)

scan

scan